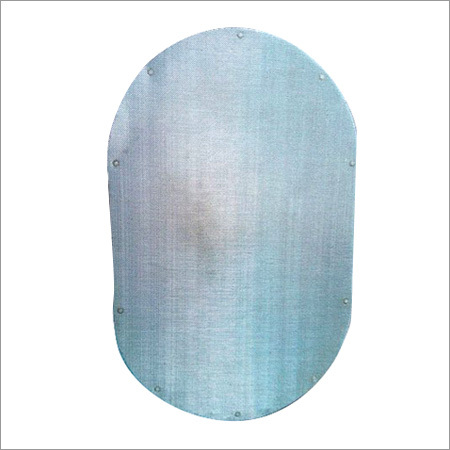

SS Filter Screen

उत्पाद विवरण:

- दक्षता (%) Up to 99%

- व्यास Available from 10 mm to 2000 mm

- प्रतिरोध Corrosion and abrasion resistant

- क्षमता Varies as per requirement

- टाइप करें

- मटेरियल

- मोटाई Available from 0.5 mm to 10 mm

- Click to view more

X

मूल्य और मात्रा

- 100

- टुकड़ा/टुकड़े

- Customised to design

- Polished, galvanised, matt

- Round, rectangular, custom shapes

- Custom as per specification

- Welded, framed, or crimped edges

- 5 microns to 50 mm

- Flanged, threaded or plain end

- Up to 15 bar

उत्पाद की विशेषताएं

- Available from 10 mm to 2000 mm

- Up to 99%

- Available from 0.5 mm to 10 mm

- Corrosion and abrasion resistant

- Up to 800°C

- Minimal

- Varies as per requirement

- Water filtration, chemical processing, pharmaceutical, food and beverage industries

- Customised to design

- Polished, galvanised, matt

- Round, rectangular, custom shapes

- Custom as per specification

- Welded, framed, or crimped edges

- 5 microns to 50 mm

- Flanged, threaded or plain end

- Up to 15 bar

व्यापार सूचना

- टेलीग्राफिक ट्रांसफर (T/T), चेक

- ग्राहक की आवश्यकता के अनुसार प्रति दिन

- 2 दिन

- Yes

- मुफ्त नमूने उपलब्ध हैं

- ऑल इंडिया

उत्पाद विवरण

We are a flourished enterprise which is engaged as the manufacturers and suppliers for SS Filter Screen from a very long time in the past. These high class products are manufactured with the usage of best quality raw materials and cutting edge technology by our experts. अधिकover, this SS screen for filtrations has wide applications in the boiler and agricultural industry for the filtration process. Further, due to its superior quality, they are highly acknowledged in the industry and are being offered at market competitive prices and in a stringent time frame.

Features:

Features:

- Optimum quality

- Long lasting

- Suitable for filtration process

- Quality approved

Specification

- Material :Stainless Steel

- Material Grade :SS-304

- Filter Rating :27%-56%

- Application :Chemical Lab, Industry

Customizable Design for Diverse Applications

SS Filter Screens are available in round, rectangular, and custom shapes, with tailored dimensions and mesh sizes to meet specific operational needs. Choose from a range of edge treatments and finishes, ensuring integration into various filtration setups across industries.

Superior Performance Under Harsh Conditions

Constructed from high-grade stainless steel, these screens offer exceptional durability, resistance to corrosion and abrasion, and minimal thermal shrinkage. They operate efficiently under pressures up to 15 bar and temperatures up to 800C, making them suitable for demanding environments.

FAQs of SS Filter Screen:

Q: How can I select the right mesh size for my filtration requirements?

A: Mesh size should be determined by your desired filtration precisionsmaller micron sizes filter finer particles. Our SS Filter Screens range from 5 microns to 50 mm, allowing selection based on the specific needs of water filtration, chemical processing, pharmaceutical, or food and beverage applications.Q: What edge treatments are available for the filter screens, and why do they matter?

A: We offer welded, framed, and crimped edge treatments. The choice impacts durability, ease of installation, and suitability for particular system pressures or flow conditions. We recommend consulting with our technical team for guidance based on your operating environment.Q: Where are SS Filter Screens typically used?

A: Our filter screens are utilized across industries including water filtration, chemical processing, pharmaceutical manufacturing, and food and beverage production, due to their reliability, efficiency, and ability to withstand harsh operational conditions.Q: What is the process for customizing the screens dimensions and porosity?

A: Customization involves sharing your filtration specifications including required mesh size, shape, length, edge treatment, porosity, and connection type. Our manufacturing team will design and produce screens tailored to these parameters to ensure optimal performance in your system.Q: When should stainless steel filter screens be considered over alternative materials?

A: Choose stainless steel filter screens when high resistance to corrosion, abrasion, and extreme temperatures is requiredespecially in chemical, pharmaceutical, and food industry environments where durability and hygiene are paramount.Q: How does the pressure rating impact the filter screens usage?

A: With a pressure rating of up to 15 bar, these screens perform safely under significant operational pressures, making them suitable for high-flow or pressurized systems commonly found in industrial filtration processes.Q: What benefits do woven and perforated filter screens offer compared to other types?

A: Woven screens provide precise filtration for fine particles, while perforated screens are ideal for higher flow rates and mechanical strength. Both types offer high efficiency (up to 99%) and can be tailored to specific filtration tasks.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email