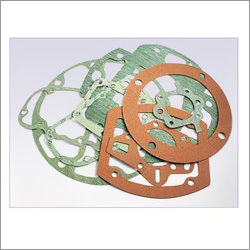

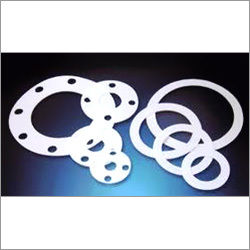

Die Cut Gasket

10-500 INR/Unit

Product Details:

- Working Temperature -40C to +250C

- Standard ASTM, DIN, IS or as per drawing/specification

- Hardness 70-90 Shore A

- Temperature Resistance Up to 250C

- Pressure Resistance Up to 150 bar

- Medium Water, Oil, Chemicals, Steam

- Gasket Coefficient 0.25 - 0.4

- Click to view more

X

Die Cut Gasket Price And Quantity

- 10-500 INR/Unit

- 10 Piece

Die Cut Gasket Product Specifications

- ASTM, DIN, IS or as per drawing/specification

- Available on request

- 70-90 Shore A

- Available on request

- Industrial sealing, Flange joints, Valve packing

- -40C to +250C

- Custom as per requirement

- 3 mm

- Non-asbestos, Rubber, Graphite, or as specified

- Full vacuum to positive pressure

- Round, Oval, Rectangular, or Custom Die-cut

- Up to 150 bar

- Up to 250C

- 0.25 - 0.4

- Water, Oil, Chemicals, Steam

Die Cut Gasket Trade Information

- 100 Piece Per Day

- 10-500 Days

- Yes

- Free samples are available

- All India

Product Description

We are offering our esteemed clients the best quality Die Cut Gasket as the leading manufacturers and suppliers from Bhosari, Maharashtra. We are having an expert team of professionals who has immense knowledge and expertise for this domain and they work in accordance with the set industry norms. Moreover, this die cut gasket is widely used in various industries to stick together two components and to seal them altogether. Further, these products are being offered at cost effective prices and in a stringent time frame.Features:

- Rugged design

- Sturdy construction

- Abrasion resistance

- Top quality

Versatile Material Selection

Die Cut Gaskets can be crafted from non-asbestos, rubber, graphite, or custom-specified materials, facilitating compatibility with a broad range of media, including water, oil, chemicals, and steam. This flexibility enables application across various industries requiring reliable sealing solutions.

Custom Shapes and Sizes

With die-cutting manufacturing, gaskets can be tailored to specific requirements, whether round, oval, rectangular, or uniquely shaped. The option for custom thickness (3 mm standard) and size ensures optimal fit and performance in industrial sealing, flange joints, and valve packing.

Robust Performance Under Pressure

Engineered for durability, these gaskets withstand temperatures ranging from -40C to +250C and pressures up to 150 bar, offering low compression set and excellent elongation at break. Their high hardness (70-90 Shore A) ensures integrity, even in harsh environments.

FAQs of Die Cut Gasket:

Q: How are Die Cut Gaskets manufactured, and what advantages does die-cutting provide?

A: Die Cut Gaskets are produced using precision die-cutting techniques, which allow for accurate shaping and sizing based on design specifications. This method ensures tight tolerances, consistency across units, and the ability to fulfill custom shape and size requirements for specific industrial applications.Q: What media can these Die Cut Gaskets safely seal against?

A: These gaskets are suitable for sealing against water, oil, chemicals, and steam. Their robust material selection and properties enable reliable performance in environments involving aggressive fluids and temperature variations.Q: When should I opt for an embossed or smooth surface finish on my gasket?

A: A smooth surface finish is often preferred for applications requiring leak-proof seals on machined flange surfaces, while embossed finishes can enhance grip and sealing performance on irregular or textured surfaces. The choice depends on application and sealing requirements.Q: Where can these gaskets be used, and what are typical industrial applications?

A: Die Cut Gaskets are commonly used in industrial sealing, flange joints, and valve packing. They are suitable for deployment in chemical processing, water treatment, oil and gas, steam systems, and anywhere reliable sealing is critical.Q: What are the benefits of optional adhesive backing for these gaskets?

A: Adhesive backing simplifies installation, ensuring the gasket remains in place during assembly. This is particularly advantageous in overhead or vertical applications and can help prevent misalignment during mounting, saving assembly time.Q: How does the gaskets temperature and pressure resistance contribute to its performance?

A: With temperature resistance up to 250C and pressure tolerance up to 150 bar, these gaskets maintain effective sealing under harsh operating conditions. Their resilience against thermal and mechanical stresses preserves equipment integrity and reduces maintenance frequency.Q: Can custom sizes, shapes, and rings be requested for special applications?

A: Yes, Die Cut Gaskets can be custom-fabricated in any required size or shape, with inner and outer rings available upon request. The manufacturing process supports tailored solutions to suit unique application needs, ensuring optimal fit and performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email