Foundry Filter

Product Details:

- Product Type Foundry Filter

- General Use Industrial Air Filtration

- Material Ceramic

- Type Panel Filter

- Capacity Customizable as per requirement

- Weight (kg) 0.8 1.2

- Computerized No

- Click to view more

X

Foundry Filter Price And Quantity

- INR

- Up to 1500°C

- Metal Casting, Foundries, Steel Plants

- Carton/Pallet

- Efficient removal of non-metallic inclusions

- Rectangular/Square

- Smooth

- Optimized for impurity removal

- Long service life, reusable

Foundry Filter Product Specifications

- Manual

- Industrial Air Filtration

- No

- Orange/Light Brown

- Foundry Filter

- Standard/Custom sizes available

- No

- Panel Filter

- High thermal shock resistance, chemical durability, easy to install

- 0.8 1.2

- No

- Ceramic

- 150 mm x 50 mm x 22 mm

- Customizable as per requirement

- High Efficiency (98%)

- No

- Up to 1500°C

- Metal Casting, Foundries, Steel Plants

- Carton/Pallet

- Efficient removal of non-metallic inclusions

- Rectangular/Square

- Smooth

- Optimized for impurity removal

- Long service life, reusable

Product Description

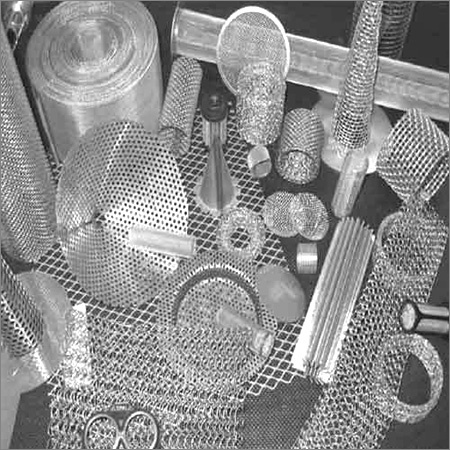

Backed by a team of diligent professionals, we are known to be the expert manufacturers and suppliers of Foundry Filter from many years in the industry. Our team of experts have huge amount of knowledge which helps in the manufacturing process. Also, all the manufactured products are tested on various parameters so that the best quality product is been delivered to the client. Moreover, this foundry filter is highly used in boiling and agricultural industries. Furthermore, all these products are being offered at industry leading prices and in no time constraint.

Features:

Features:

- Sturdy construction

- Fine quality

- Rugged design

- Precise finishing

Specification

- Thickness :0.5-10 mm

- Material Grade :SS-304

- Material: Stainless Steel

Optimized Impurity Removal for Metal Casting

Designed for metal casting, foundries, and steel plants, the ceramic Foundry Filter excels at removing non-metallic inclusions by harnessing its efficient porosity. It operates at temperatures up to 1500C and improves the purity of molten metal, resulting in higher quality and stronger products. Its application ensures that end users benefit from minimized defects and enhanced performance during industrial air filtration.

Exceptional Durability and Reusability

Constructed with high thermal shock resistance and chemical durability, the filter boasts long service life. The reusable design reduces overall replacement costs, making it an economical and sustainable solution for demanding environments. Industries requiring repetitive and continuous operations benefit greatly from its robust performance, minimizing downtime and maintenance frequency.

Customizable for Diverse Requirements

The Foundry Filter accommodates standard and custom dimensions, including various panel sizes. High filtration efficiency (98%) and capacity modification options make it suitable for a wide range of industrial installations. Manufacturers and suppliers in India can tailor filter area, flow rate, and packaging to address unique operational needs of each client, ensuring optimal fit and value.

FAQs of Foundry Filter:

Q: How does the Foundry Filter improve impurity removal in metal casting processes?

A: The Foundry Filter utilizes optimized ceramic porosity to efficiently trap and remove non-metallic inclusions from molten metal. This process ensures cleaner metal output, reduces casting defects, and enhances the overall quality of products manufactured in foundries and steel plants.Q: What are the benefits of the filters long service life and reusability?

A: With high thermal shock resistance and chemical durability, the filter can operate over extended periods without needing frequent replacement. Its reusable nature lowers maintenance costs and helps reduce waste, providing economic and operational advantages to industrial users.Q: When should I use this filter in my foundry or steel plant?

A: The Foundry Filter is best utilized during metal casting operations or any process requiring efficient removal of impurities from molten metal at high temperatures. Its design makes it an excellent choice for continuous, high-efficiency industrial air filtration tasks.Q: Where is the Foundry Filter typically installed within industrial settings?

A: It is generally installed directly in the filtration area of metal casting setups, foundries, and steel plants. Its panel design and easy installation features allow placement in various configurations to suit standard or custom-sized systems, enhancing process versatility.Q: What is the installation process like for the Foundry Filter?

A: The filter is designed for easy manual installation in industrial systems. It can be swiftly placed in designated frames or filtration zones without the need for specialized equipment or computerized controls, aimed at streamlining setup for operators.Q: How customizable is the filter to suit different operational requirements?

A: Manufacturers offer the filter in standard or custom sizes and capacities, allowing users to match filtration area, flow rate, and physical dimensions to their specific needs. Packaging options, such as carton or pallet, can be adjusted based on order quantity and site logistics.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email